Amber extends rally after clarification on demerger; soars 31% in 5 days

Amber extends rally after clarification on demerger; soars 31% in 5 days

- NSE

- BSE

Last Updated: Dec 26 2024 | 03:24 PM IST

- 1D

- 5D

- 1M

- 6M

- 1Y

- 5Y

- MAX

Precision Aluminum Products: Applications in Aerospace, Automotive, Electronics, and More.

Precision Aluminum Products: Applications in Aerospace, Automotive, Electronics, and More.

Precision aluminium products have become increasingly popular across a range of industries due to their versatility, strength, and lightweight properties. In this case study, we’ll examine how precision aluminium products have been applied in aerospace, automotive, electronics, and other industries.

One of the key reasons why our company, i.c.e Aluminium, is the ideal partner for providing precision aluminium products to various industries is our commitment to quality and innovation. We use advanced manufacturing techniques and cutting-edge technology to produce high-quality precision aluminium products that meet the specific needs of our clients.

For example, in the aerospace industry, precision aluminium products are used for various aircraft components, including fuselage, wings, and landing gear. Our precision aluminium products have been successfully used in aircraft manufacturing due to their strength, corrosion resistance, and durability.

Similarly, in the automotive industry, precision aluminium products are used in the production of engine blocks, transmission cases, and suspension components. Our precision aluminium products are known for their high strength-to-weight ratio, which makes them an ideal choice for automotive applications.

In the electronics industry, precision aluminium products are used for heat sinks, computer components, and other applications. Our precision aluminium products have excellent thermal conductivity, which makes them highly effective in dissipating heat, ensuring the efficient operation of electronic devices.

In conclusion, precision aluminium products are increasingly being used in various industries due to their versatility, strength, and lightweight properties. As a leading manufacturer of precision aluminium products, our company is committed to providing high-quality, innovative solutions to our clients. Contact us today to learn more about our precision aluminium products and how we can meet your specific needs.

Copper How Is Copper a Better Material for Cooling

Copper How Is Copper a Better Material for Cooling

Air conditioning systems are not just a luxury anymore, but a necessity in homes, offices and various industrial settings. As global temperatures continue to rise, so does the need for effective, reliable cooling systems. To fulfil this requirement, manufacturers tested various materials for optimal cooling. One such substance that stood out is copper — 100% Copper ACs are dominating with a 98% market share.

But what is the reason for this? Let us take a deeper dive.

How Does Copper Contribute to Quicker Room Cooling?

Thermal conductivity is the rate at which heat can move through a material. The higher this rate, the faster the material can transfer heat from one place to another. Copper’s thermal conductivity is approximately 400 W/m-K, significantly higher compared to other common metals like aluminium (around 235 W/m-K). In air conditioning units, high thermal conductivity is very crucial as it can quickly absorb and dissipate heat. This helps the AC cool down a room much faster while using less energy.

How Does Copper Help in Reducing Energy Consumption?

Another key property that makes copper ideal for air conditioning is its low specific heat. Specific heat is the amount of energy needed to raise the temperature of a material by one degree Celsius. A lower specific heat indicates that a material heats up and cools down more rapidly. This is crucial in air conditioning applications, where efficient and quick heat transfer is essential.

Copper’s specific heat compared to aluminium is lower, meaning it can achieve temperature changes faster. This enhances the overall efficiency of the AC unit and contributes to energy savings.

How Does Copper Improve the Lifespan of AC Units?

Copper has high anti-corrosion properties compared to aluminium, which prevents the leakage of gases and improves the lifespan of 100% Copper ACs. Copper is also more durable, making it much easier to clean and repair.

Its durability also helps its long-term energy efficiency. For instance, a 5-star rated aluminium condenser AC can degrade to almost 1 star within 2–3 years, whereas a 100% copper AC can maintain a 3-star rating over the same period.

According to the U.S. Department of Energy, more efficient AC systems can lead to a reduction in overall energy consumption by 20% to 50%. By using copper in these systems, manufacturers can create air conditioners that are both energy-efficient and environmentally friendly. The reduced energy consumption also lowers greenhouse gas emissions, supporting broader sustainability goals.

Copper: The Future of Sustainability

Copper’s properties like high corrosion resistance and durability, excellent thermal conductivity and low specific heat capacity make it an ideal material in modern cooling systems. It can cool your home faster while consuming less energy and doesn’t put a lot of burden on the parts of your ACs, like the compressor. As a result, copper is not only beneficial for individual consumers but also contributes to broader environmental sustainability efforts. These factors prove that copper is the ideal material for cooling. So rest easy knowing your 100% Copper AC is providing you with the best cooling.

Advancing Industries with Excellence: Unveiling the Power of I.C.E Aluminium

Advancing Industries with Excellence: Unveiling the Power of I.C.E Aluminium

In a world where quality, innovation, and reliability are paramount, I.C.E Aluminium Pte Ltd emerges as a dynamic force in the aluminium industry. With a passion for excellence and a commitment to customer satisfaction, we have become a trusted partner for businesses seeking high-quality aluminium products. In this blog, we delve into the essence of I.C.E Aluminium and how our company is shaping industries with our exceptional offerings.

-

Unparalleled Expertise and Precision: At I.C.E Aluminium, we bring together a team of skilled professionals with extensive experience in the field. Our expertise in aluminium extrusion, CNC machining, and surface finishes allows us to deliver products of unparalleled precision and quality. With advanced manufacturing processes and cutting-edge technology, we ensure that every product meets the highest industry standards.

-

Diverse Applications and Industries: Our wide range of aluminium products finds application across various industries. From construction to automotive, aerospace to electronics, we cater to the unique needs of each sector. Whether it’s designing robust components for aircraft or creating sleek and durable facades for architectural projects, I.C.E Aluminium has the capabilities to fulfil diverse requirements.

-

Sustainability and Innovation: As a responsible corporate entity, I.C.E Aluminium is committed to sustainability and environmental stewardship. We strive to minimize waste, reduce energy consumption, and implement eco-friendly practices throughout our manufacturing processes. Our dedication to innovation drives us to explore new technologies and materials, ensuring that our products are at the forefront of industry advancements.

-

Collaborative Partnerships and Customer Satisfaction: At the core of our success lies our customer-centric approach. We believe in building strong, collaborative partnerships with our clients, understanding their unique requirements, and delivering tailor-made solutions. Our dedicated customer support team ensures a seamless experience from project inception to product delivery, guaranteeing customer satisfaction at every step.

I.C.E Aluminium Pte Ltd stands as a beacon of excellence in the aluminium industry. With our unwavering commitment to precision, innovation, and customer satisfaction, we continue to shape industries and empower businesses with our high-quality aluminium products. Join us on this journey of advancement and discover the unparalleled power of I.C.E Aluminium.

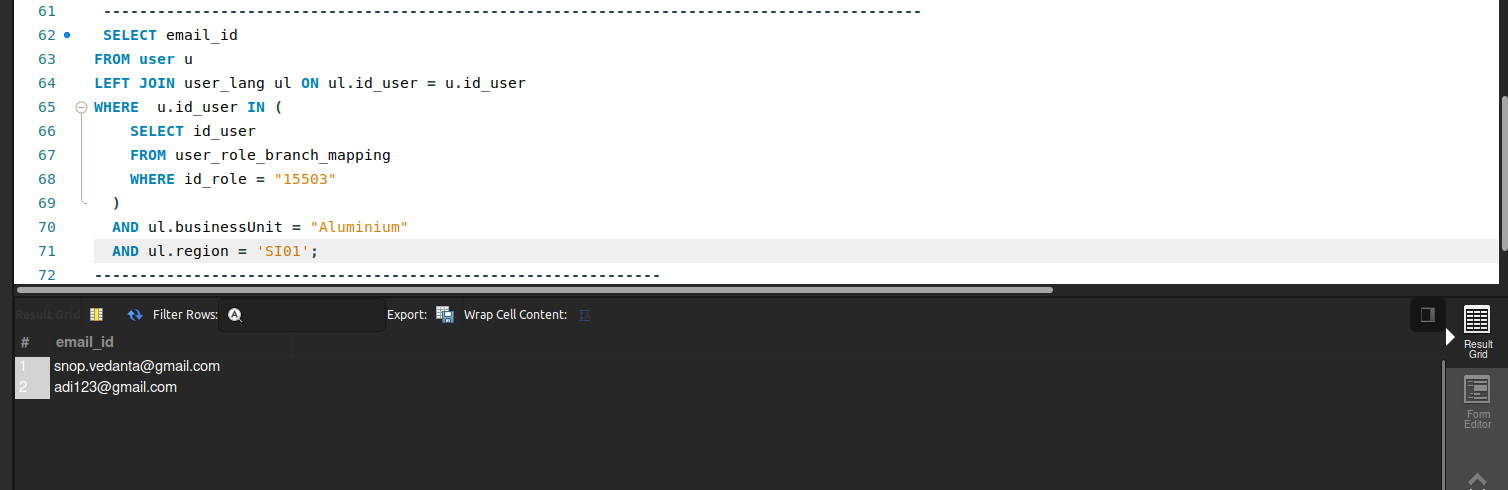

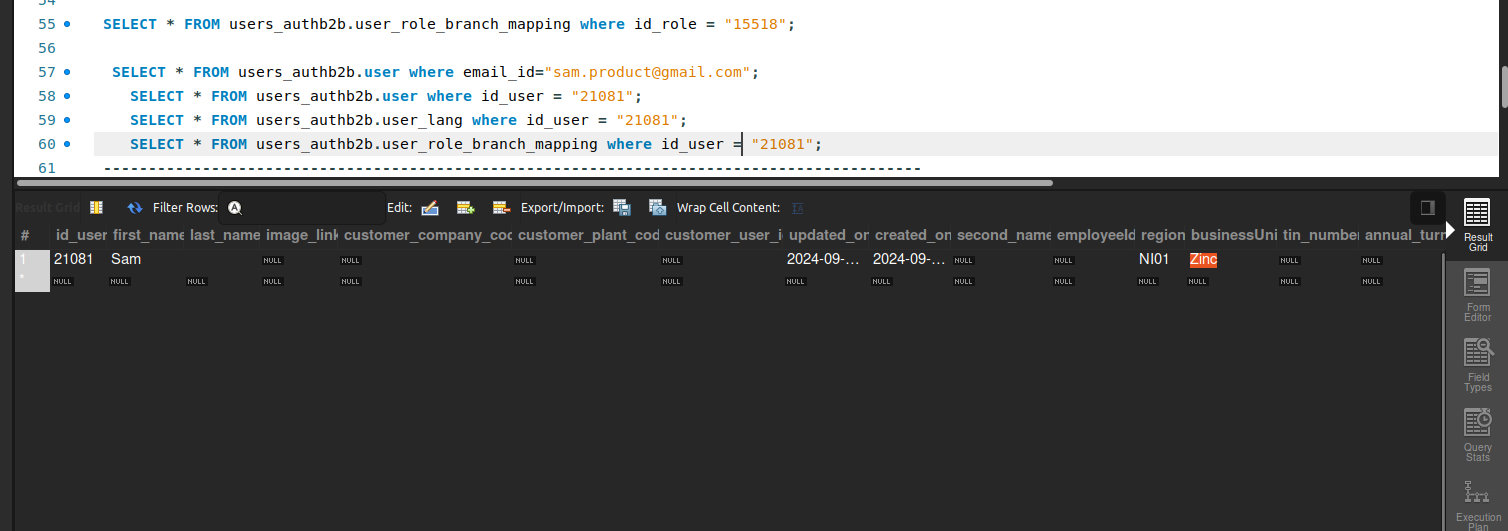

BUg

BUg

This is not developer bug

Advancing Industries with Excellence: Unveiling the Power of I.C.E Aluminium

Advancing Industries with Excellence: Unveiling the Power of I.C.E Aluminium

In a world where quality, innovation, and reliability are paramount, I.C.E Aluminium Pte Ltd emerges as a dynamic force in the aluminium industry. With a passion for excellence and a commitment to customer satisfaction, we have become a trusted partner for businesses seeking high-quality aluminium products. In this blog, we delve into the essence of I.C.E Aluminium and how our company is shaping industries with our exceptional offerings.

-

Unparalleled Expertise and Precision: At I.C.E Aluminium, we bring together a team of skilled professionals with extensive experience in the field. Our expertise in aluminium extrusion, CNC machining, and surface finishes allows us to deliver products of unparalleled precision and quality. With advanced manufacturing processes and cutting-edge technology, we ensure that every product meets the highest industry standards.

-

Diverse Applications and Industries: Our wide range of aluminium products finds application across various industries. From construction to automotive, aerospace to electronics, we cater to the unique needs of each sector. Whether it’s designing robust components for aircraft or creating sleek and durable facades for architectural projects, I.C.E Aluminium has the capabilities to fulfil diverse requirements.

-

Sustainability and Innovation: As a responsible corporate entity, I.C.E Aluminium is committed to sustainability and environmental stewardship. We strive to minimize waste, reduce energy consumption, and implement eco-friendly practices throughout our manufacturing processes. Our dedication to innovation drives us to explore new technologies and materials, ensuring that our products are at the forefront of industry advancements.

-

Collaborative Partnerships and Customer Satisfaction: At the core of our success lies our customer-centric approach. We believe in building strong, collaborative partnerships with our clients, understanding their unique requirements, and delivering tailor-made solutions. Our dedicated customer support team ensures a seamless experience from project inception to product delivery, guaranteeing customer satisfaction at every step.

I.C.E Aluminium Pte Ltd stands as a beacon of excellence in the aluminium industry. With our unwavering commitment to precision, innovation, and customer satisfaction, we continue to shape industries and empower businesses with our high-quality aluminium products. Join us on this journey of advancement and discover the unparalleled power of I.C.E Aluminium.

Unveiling the Latest News and Trends in the Aluminium Industry

Unveiling the Latest News and Trends in the Aluminium Industry

Stay ahead of the curve with the latest news, trends, and developments in the aluminium industry. In this blog, we’ll explore exciting updates on new technologies, market prospects, industry reports, and more. Join us as we dive into the dynamic world of aluminium and discover what’s shaping the future of this thriving industry.

1. New Technological Advancements:

Explore the cutting-edge technologies that are revolutionizing the aluminium industry. From advanced manufacturing processes to innovative surface treatments, discover how these advancements are enhancing product quality, efficiency, and sustainability.

2. Market Outlook and Growth Opportunities:

Gain insights into the current market outlook and future growth prospects of the aluminium industry. Discover key factors driving market demand, emerging applications, and potential business opportunities for stakeholders across the value chain.

3. Industry Reports and Analysis:

Delve into in-depth industry reports and analyses that provide a comprehensive overview of the aluminium sector. Uncover key market trends, challenges, and growth drivers, enabling you to make informed decisions and strategic plans for your business.

4. Sustainability Initiatives and Environmental Impact:

Learn about the latest sustainability initiatives within the aluminium industry, including recycling efforts, energy-efficient practices, and carbon footprint reduction. Discover how industry players are addressing environmental concerns and driving the transition towards a more sustainable future.

Stay informed and be at the forefront of the aluminium industry with our blog, where we share the latest news, trends, and developments. From breakthrough technologies to market insights and sustainability efforts, stay connected to the pulse of the industry. Join us as we navigate the exciting world of aluminium and uncover the opportunities that lie ahead.

Remember to subscribe to our blog for regular updates on the latest news and trends in the aluminium industry!

Enhancing Sustainability in the Aluminium Industry: Our Commitment and Initiatives

Enhancing Sustainability in the Aluminium Industry: Our Commitment and Initiatives

At I.C.E Aluminium, we are dedicated to making a positive impact on the environment and society through our sustainable practices. In this blog, we will highlight our commitment to sustainability and share the initiatives we have implemented to reduce our environmental footprint, promote responsible sourcing, and support the circular economy.

1. Sustainable Manufacturing Processes:

Discover how we have optimized our manufacturing processes to minimize energy consumption, reduce greenhouse gas emissions, and minimize waste generation. Learn about our investments in advanced technologies and equipment to improve efficiency and enhance the sustainability of our operations.

2. Responsible Sourcing and Supply Chain:

Explore our efforts to ensure responsible sourcing of raw materials, including aluminium. We prioritize suppliers who adhere to ethical and environmental standards, promoting transparency and accountability throughout our supply chain. Learn about our certifications and partnerships that validate our commitment to responsible sourcing.

3. Recycling and Circular Economy:

Learn how we actively promote the circular economy by integrating recycled aluminium into our production processes. We will discuss our recycling initiatives, partnerships with recycling facilities, and the benefits of using recycled aluminium in reducing energy consumption and conserving natural resources.

4. Innovation for Sustainability:

Discover our ongoing research and development efforts to develop innovative solutions that further enhance sustainability in the aluminium industry. We will share examples of our projects and collaborations aimed at advancing technologies, such as lightweight alloys, energy-efficient processes, and sustainable product design.

At I.C.E Aluminium, sustainability is at the core of everything we do. Through our commitment to responsible practices, responsible sourcing, and innovative approaches, we strive to lead the way towards a more sustainable future for the aluminium industry. Join us in our journey towards a greener and more sustainable world.

Stay tuned for more updates on our sustainability initiatives and their impact on the aluminium industry.

Load Balancing

Load Balancing

Round-robin load balancing is the simplest and most commonly-used load balancing algorithm.

tes

tes

tedt